Payment Type:T/T

Incoterm:EXW

Transportation:Ocean

Maximum Thickness: 12mm

Strip Length: 2-16.5mm

Shearing Thickness: <8mm

Transportation: Ocean

Payment Type: T/T

Incoterm: EXW

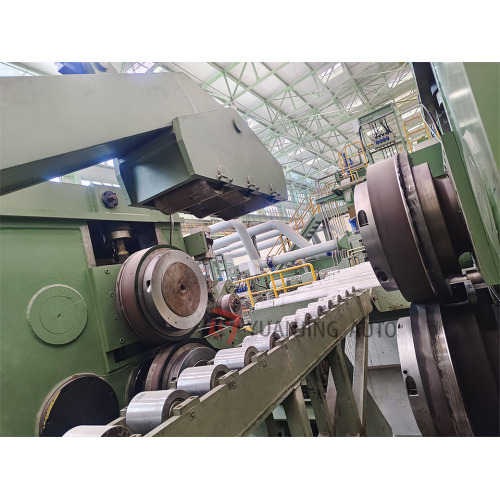

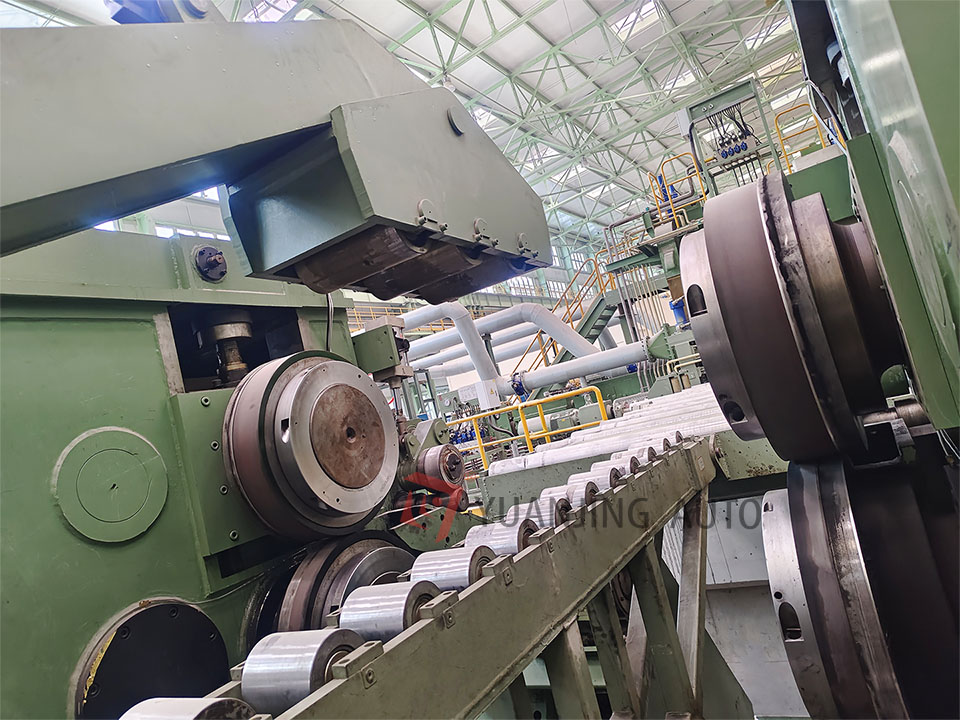

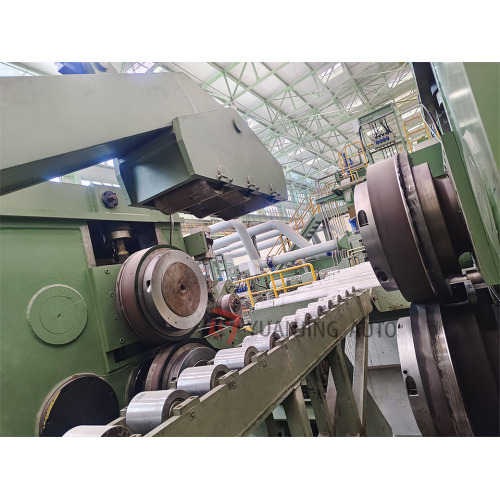

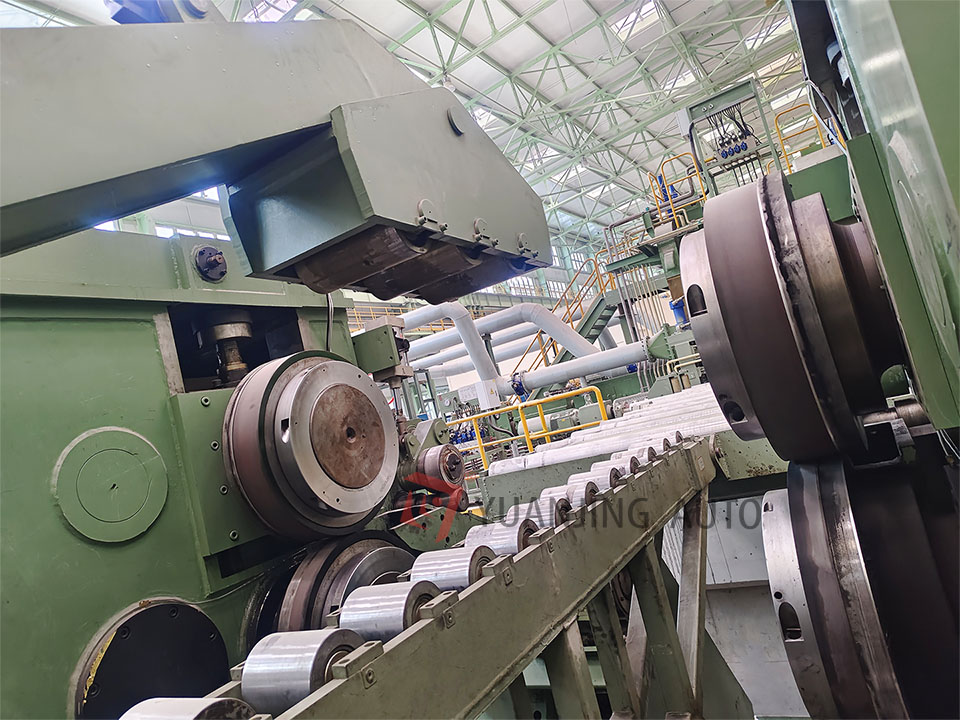

Main equipment components & sheet shearing machine

The sheet metal cutting machine consists of multiple functional modules, including coil processing, uncoiling and straightening, shearing, finished product stacking, and auxiliary systems.

Coil loading and uncoiling

Fixed saddles, coil transport trolleys, and cross saddles are responsible for loading and transporting coils.

Floor roller stations and coil measuring devices – ensure correct positioning and size inspection.

Uncoiler with CPC (centering and positioning control) – uncoils while keeping the coil aligned.

The coil loading and uncoiling system uses fixed saddles, coil transport trolleys and cross saddles to work together to achieve automatic loading and efficient transportation of coils; the coils are then smoothly transported through the floor roller station, while the coil measuring device accurately detects key dimensions such as outer diameter and width of the coils to ensure positioning accuracy for subsequent processing; finally, the uncoiler equipped with CPC (centering and positioning control) system automatically uncoils with centering. The device ensures that the strip always runs stably along the center line of the production line through real-time monitoring and automatic deviation correction functions, providing high-quality raw material supply for subsequent processes.

Our service

Worry-free after-sales service | Lifetime protection beyond the "three guarantees"

10-year warranty

Industry-leading 10-year quality assurance, free repair + parts replacement during the warranty period, allowing you to use it longer and save more.