Payment Type:T/T

Incoterm:EXW

Min. Order:1

Transportation:Ocean

Shearing Thickness: <8mm

Stacking Height: 500mm

Transportation: Ocean

Payment Type: T/T

Incoterm: EXW

Strip feeding and initial processing

The strip feeding table guides the steel coil to the processing line.

The tension control system includes double pressure rollers, deep bending rollers, and double pinch rollers to maintain the appropriate strip tension.

The side guide straightens the strip before straightening.

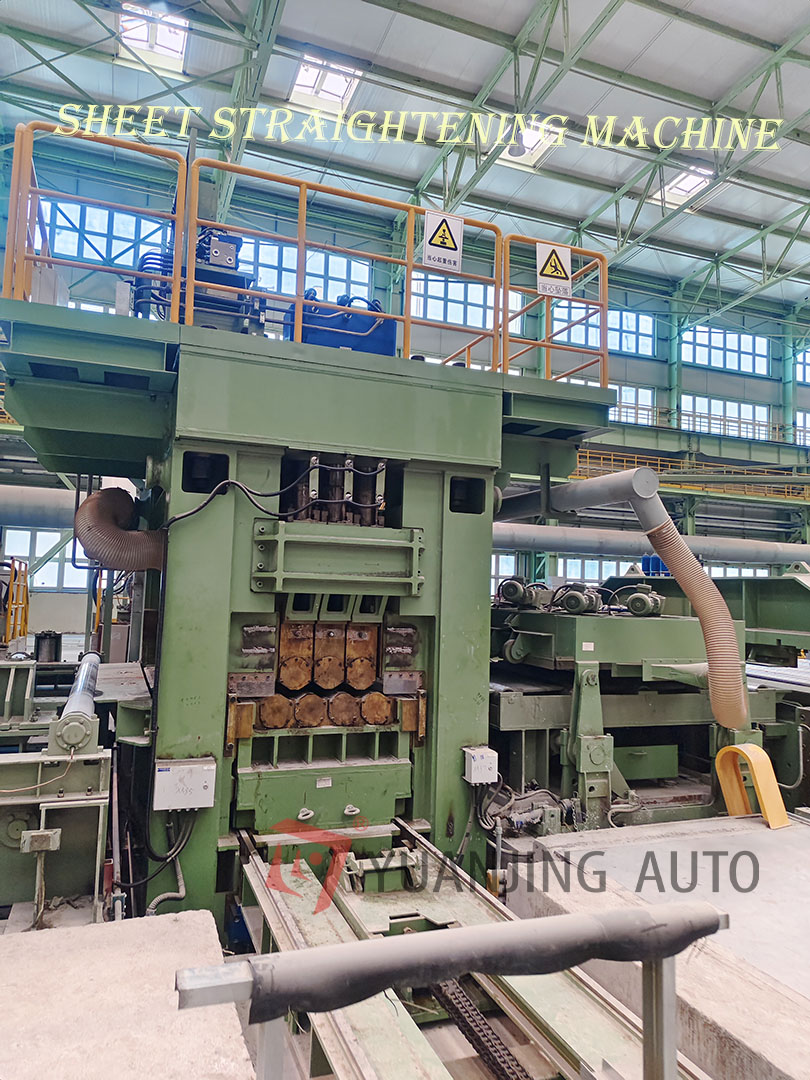

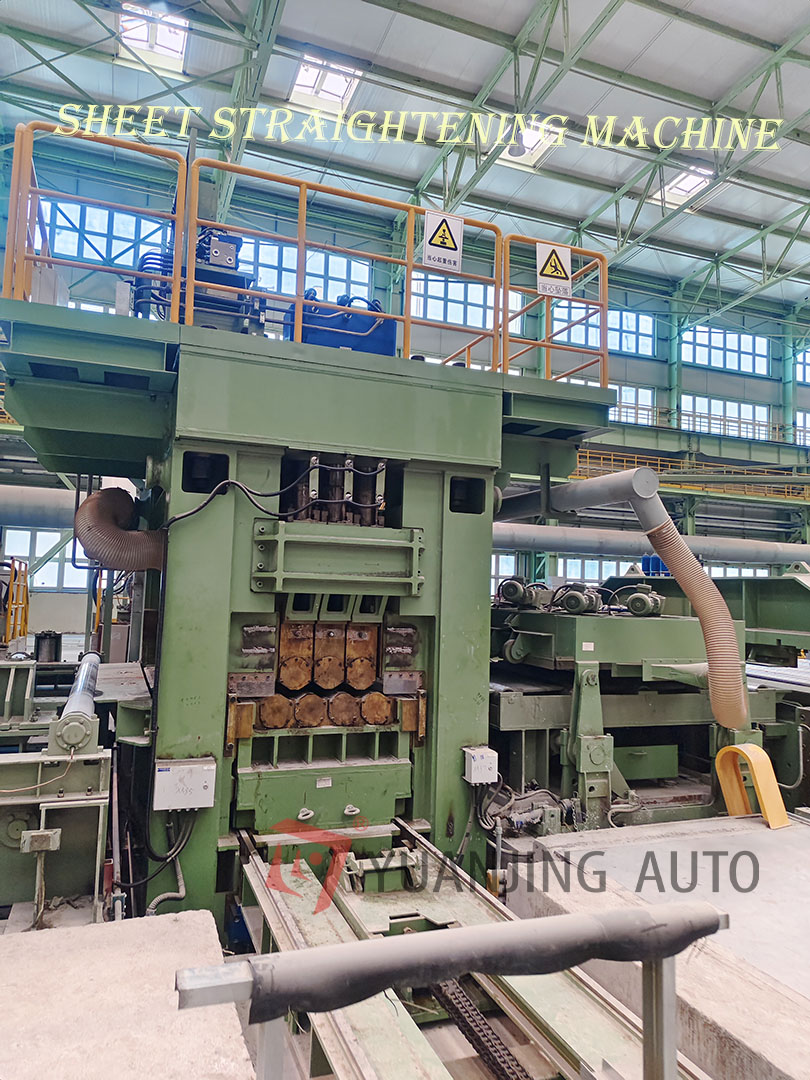

The 7-roller rough straightener pre-straightens the steel strip for further processing.

The strip feeding and initial processing system first accurately guides the uncoiled steel coil to the processing line through the strip feeding table to ensure that the strip enters the production process smoothly; then the tension control system (including double pressure rollers, deep bending rollers and double pinch rollers) applies precise tension control to the strip, effectively preventing the strip from running off and maintaining running stability; before entering the straightening process, the side guide device accurately corrects the edge of the strip to ensure that the strip runs along the center line; finally, the 7-roller rough straightener performs preliminary flattening on the strip to eliminate the original bending deformation of the steel strip, laying the foundation for the subsequent fine straightening and shearing processes. The whole system adopts automatic control, and each link cooperates closely to ensure the quality and efficiency of strip processing.