Payment Type:T/T

Incoterm:EXW

Min. Order:1

Transportation:Ocean

Shearing Range: 2m to 16.5m

Stacking Height: 500mm

Transportation: Ocean

Payment Type: T/T

Incoterm: EXW

Trimming and trimming

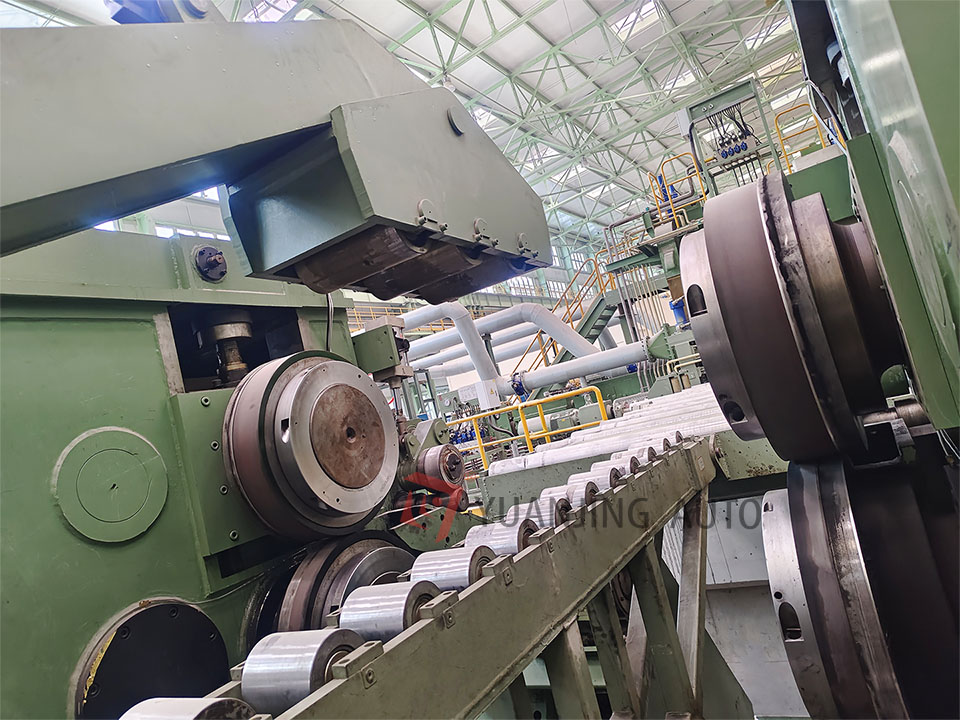

Head shear – cuts off the defective strip ends.

Scrap collection device – collects the scrap generated by trimming.

Brush plate – cleans the strip surface before trimming.

Trim shear pressure roller – accurately feeds the strip into the trimming section.

Trim shear and scrap shear – remove uneven edges and collect scrap through a dedicated system.

The strip trimming process adopts a fully automated process: first, the head shear accurately cuts off the defective part of the strip end to ensure material quality; the scrap generated by trimming is automatically recycled and processed by the scrap collection device to keep the production environment clean. Before entering the trimming process, the brush plate device thoroughly cleans the strip surface to remove the oxide layer and impurities. The trimming shear pressure roller accurately controls the strip feeding speed and position to ensure stable feeding. Finally, the trimming shears and waste shears work together to efficiently remove the uneven parts of the strip edge. At the same time, the dedicated waste collection system recycles and processes the scraps in real time. The entire trimming process is accurate and efficient, which not only ensures product quality but also realizes the automatic recycling of waste.