Payment Type:T/T

Incoterm:EXW

Min. Order:1

Transportation:Ocean

Shearing Range: 2m to 16.5m

Stacking Height: 500mm

Transportation: Ocean

Payment Type: T/T

Incoterm: EXW

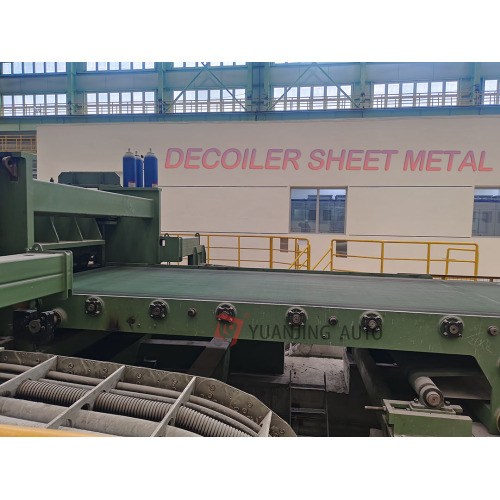

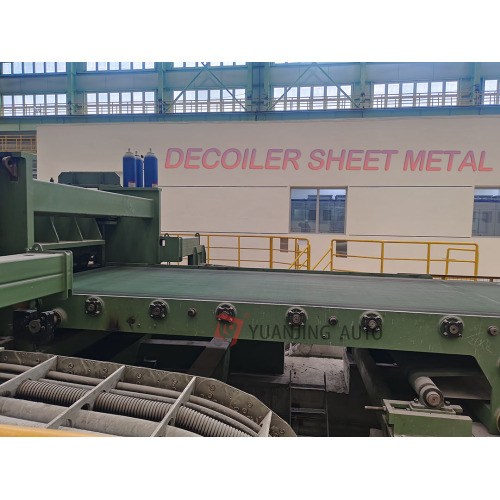

Cross-cutting Machine equipment composition

The primary tools of the cross-cutting laptop production line include a couple of useful modules such as steel coil processing, uncoiling and straightening, shearing processing, finished product stacking, and auxiliary systems.

Precision straightening and surface treatment

Side guides – Position the strip for precision straightening.

17-roller fine straightening machine – Ensures a high level of straightness.

13-roller fine straightening machine – Further improves the straightness of the strip.

Brush plate – Performs secondary surface cleaning.

Side guides – Align the strip before final cutting.

The precision straightening and surface treatment process of the strip adopts a multi-stage precision straightening process: first, the side guide plate accurately positions the running track of the strip to ensure that it maintains an ideal centering state when entering the straightening area; then the strip passes through the 17-roller precision straightening machine for the first high-precision flattening. The equipment adopts an advanced roller system configuration to eliminate subtle waveform defects and achieve a high standard of ±2mm/m straightness; to further improve the quality, the strip continues to pass through the 13-roller precision straightening machine for secondary straightening, and the internal stress is eliminated by optimizing the roll gap parameters, so that the straightness reaches the industry-leading level of ±0.3mm/m; after the straightening is completed, the high-speed rotating brush plate device performs a secondary deep cleaning of the upper and lower surfaces of the strip to effectively remove residual oxide scale and particles; finally, the final positioning correction of the side guide plate ensures that the strip enters the subsequent cutting process in a perfect posture. The entire process adopts a closed-loop control system to monitor and adjust the process parameters in real time to ensure that the treated strip has excellent straightness and surface quality.

This system of sheet shearing machine achieves ultra-flatness and a flawless surface of ±0.3mm/m of strip through multi-stage precision straightening and surface treatment processes. The closed-loop control of the entire process ensures stable quality and meets the stringent standards of high-end metal processing.